ABS, ABS/PC, ABS/PMMA, ABS/PU

Acrylonitrile Butadiene Styrene (ABS) is a common thermoplastic used to make light and rigid components. ABS is made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. The styrene gives the plastic a shiny, impervious surface. Butadiene is a rubbery substance that provides resilience even at low temperatures.

ABS can be used between -25 °C and 60 °C. The properties are created by rubber toughening, where fine particles of elastomer are distributed throughout the rigid matrix.

| APPLICATIONS |

| Luggage |

Printing |

Thermoforming |

| Advertising Stands |

Decorative Plates |

Refrigerator |

| Automotive |

Laboratory Equipment |

Packaging |

| Bus body interiors, etc |

|

|

| AVAILABLE SIZES |

| 1 MTR * 2 MTR |

1.22 MTR * 2.44 MTR |

1.5 MTR * 3 MTR |

2 MTR * 4 MTR |

Note:

- Customised size available subject to MOQ.

- Thickness: 0.5 mm – 10 mm

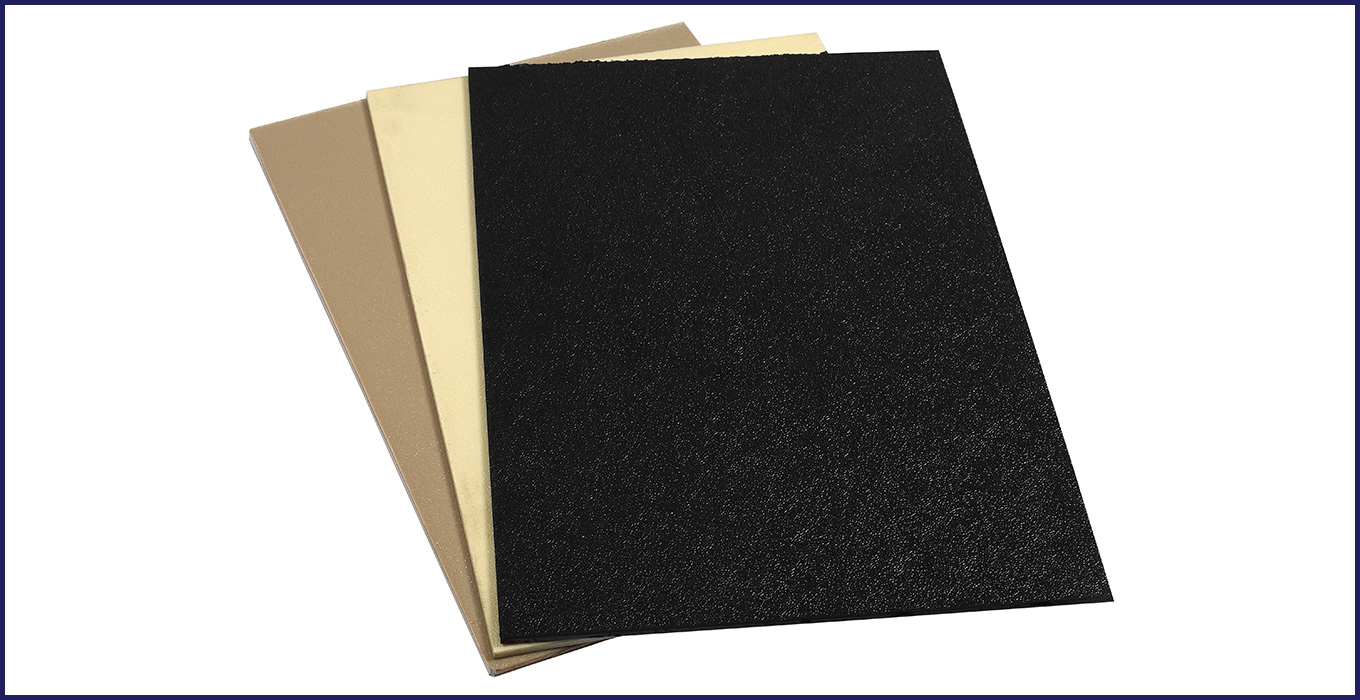

| AVAILABLE COLOURS |

| White |

Dark Grey |

Black |

Note:

Customised colours available subject to MOQ

| TEXTURES AVAILABLE |

| Universal |

Matt/Sand Finish |

Plain Glossy |

| Diamond |

Reverse Diamond |

Leather |

| Deep Embossed |

|

|

SPECIAL FEATURES

- UV Stabilised, Fire Retardant, High Impact, High Gloss & Low Gloss.

ABS/PC

The manufactured sheets based on the composition of ABS plastic and polycarbonate have higher shock resistance. ABS/PC plastic has good rigidity, high impact resistance at low temperatures, high heat resistance, and low tendency to deformation.

| APPLICATIONS |

| Luggage |

Thermoforming |

Automotive Industry |

| Electrical Appliances |

Sports Goods |

|

| AVAILABLE SIZES |

| 1 MTR * 2 MTR |

1.22 MTR * 2.44 MTR |

Note:

- Customised size available subject to MOQ.

- Thickness – 1.5 mm to 10 mm

| AVAILABLE COLOURS |

| White |

Grey |

Black |

ABS/PMMA

ABS/PMMA plastic sheet is a multilayered one. It is manufactured by coextrusion of ABS with PMMA. The top layer of impact-resistant PMMA provides scratch resistance, protection from destruction under the influence of UV rays, excellent surface quality with high gloss, resistance to acids, alkalis, fats, automotive fuels, cold-proof coolants, and cleaning substances. It also prevents bacterial growth. ABS plastic and PMMA are well-coloured, so it is possible to produce sheets of a wide range of colours.

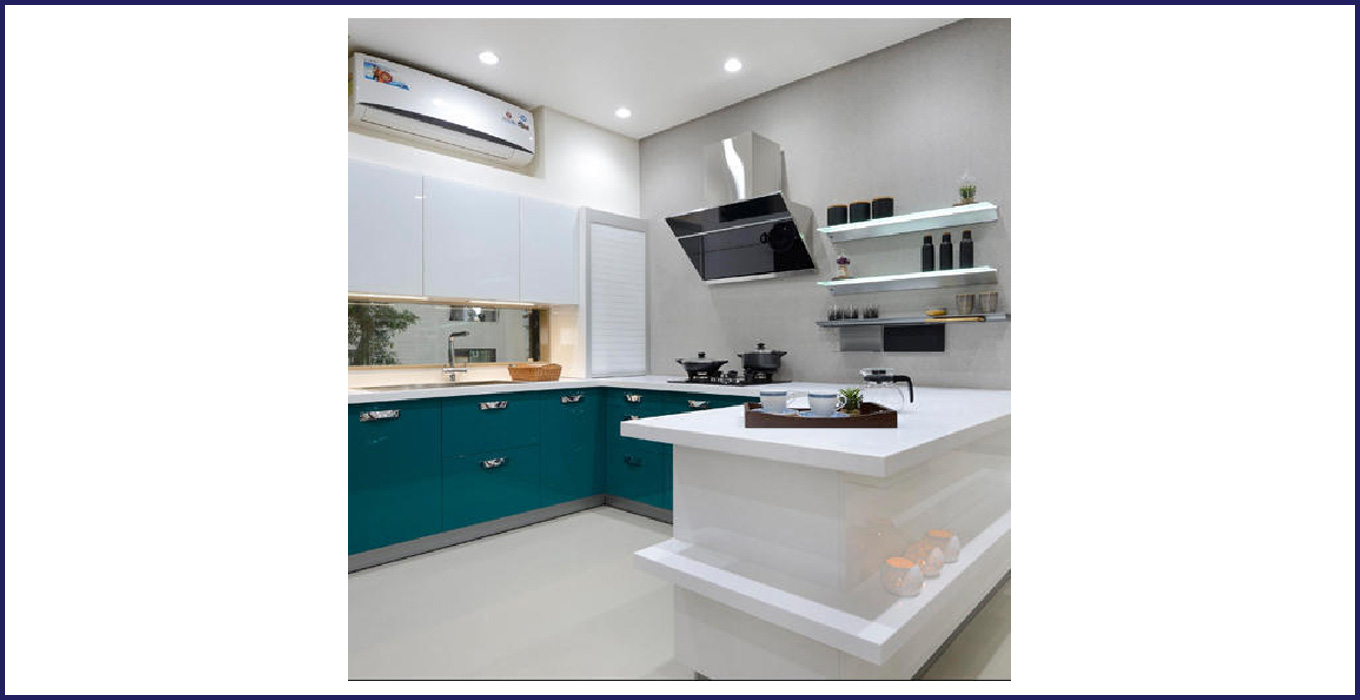

| APPLICATIONS |

| Cooler Equipment |

Bath Tubs and Sauna Equipment |

Thermoforming |

| Medical Furniture |

Façade for living room and kitchen furniture, etc. |

|

| AVAILABLE SIZES |

| 1 MTR * 2 MTR |

1.22 MTR * 2.44 MTR |

Note:

- Customised sizes available subject to MOQ

- Thickness – 1.5 mm to 10 mm

| AVAILABLE COLOURS |

| White |

Black |

|

Note:

- Customised colours available subject to MOQ

ABS/PU

Sheet plastic ABS/TPU is a multi-layered sheet with a soft surface layer from a mixture of thermoplastic polyurethane (TPU) and Acrylonitrile-butadiene-styrene (ABS), which provides high wear resistance, scratch resistance, and resistance to gasoline and lubricants. The bottom layer of ABS provides sheets with high-quality forming and high impact resistance, resistance to low temperatures. Parts made of sheet ABS/TPU have a matt (antiglare), pleasant-to-touch surface.

| APPLICATIONS |

| Thermoforming |

Interior parts of cars and external trunks |

Trays for Transportation |

| Suitcases |

Advertisement and information stand, etc. |

|

| AVAILABLE SIZES |

| 1 MTR * 2 MTR |

Note:

- Customised sizes available subject to MOQ

- Thickness – 1.5 mm – 10 mm

Note:

- Customised colours available subject to MOQ.

ABS/ASA

ABS/ASA is a multilayer sheet with guaranteed weather resistance for a period of 5-7 years. It provides an excellent high impact resistance of ABS, and UV Resistance of ASA. These sheets provide higher elasticity and durability.

| APPLICATIONS |

| Construction industry (Facades, roofs, etc) |

Automotive Industry |

Suitcases |

| Advertising products |

Lighting etc |

|

| AVAILABLE SIZES |

| 1 MTR * 2 MTR |

1.22 MTR * 2.44 MTR |

Note:

- Customised sizes available subject to MOQ

- Thickness – 1.5 mm – 10 mm

| AVAILABLE COLOURS |

| White |

Black |

Note:

- Customised colours available subject to MOQ.